Description

Ensures reliable ignition and extended durability in high-temperature furnace environments, reducing maintenance costs and downtime.

Furnace Operators – Ignite Faster, Last Longer

Rapid Heating

Reaches 1000°C in 10 seconds, minimizing startup time.

High Temperature Resistance

Operates reliably at 1100-1300°C (2012-2372°F), withstanding extreme conditions.

Long Lifespan

Up to 10 years or 90,000 hours of continuous use, reducing replacement frequency.

Customizable Flange

Available in ceramic, stainless steel, or copper options to match specific furnace designs.

Chemical & Oxidation Resistant

Maintains performance in harsh environments, preventing corrosion and degradation.

Features

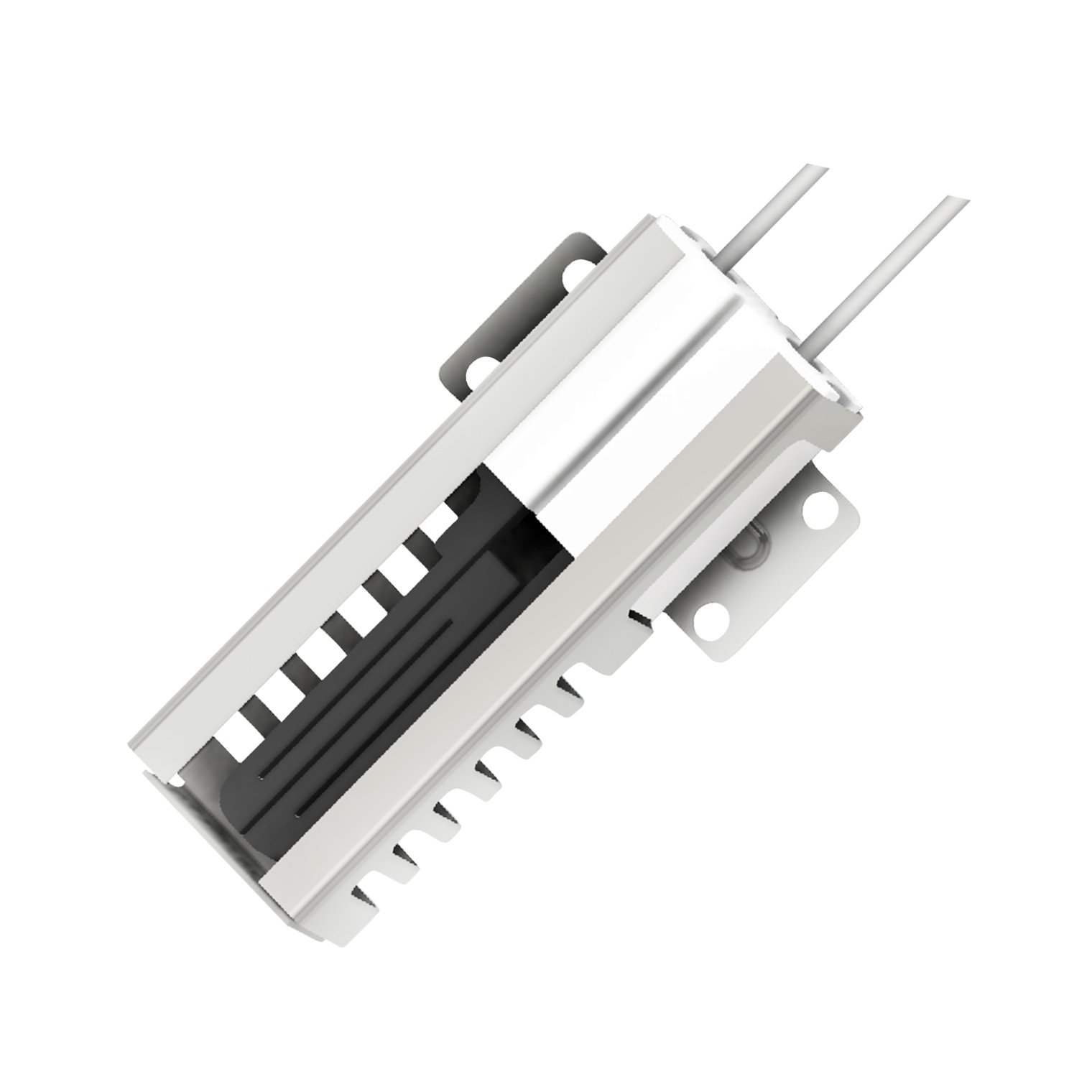

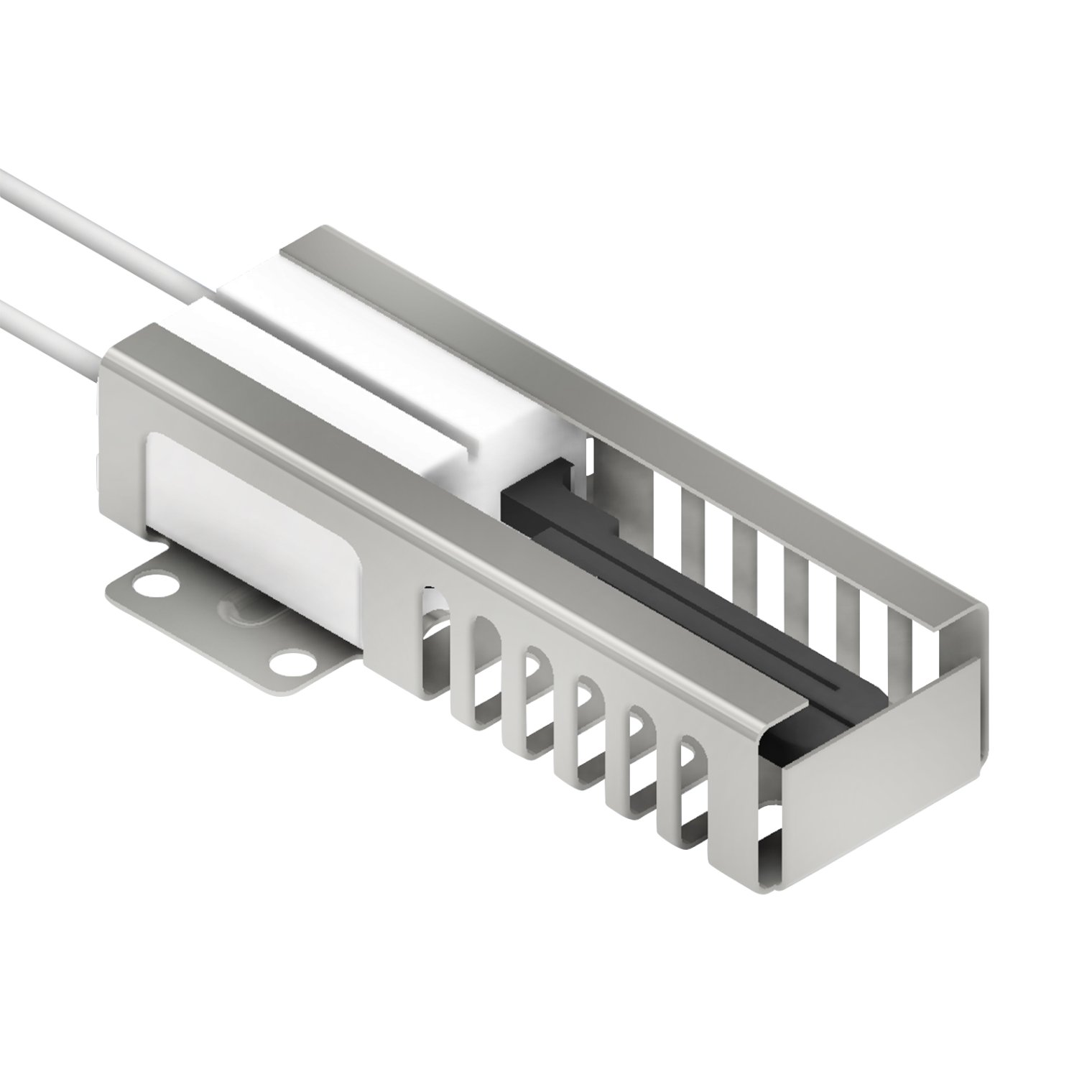

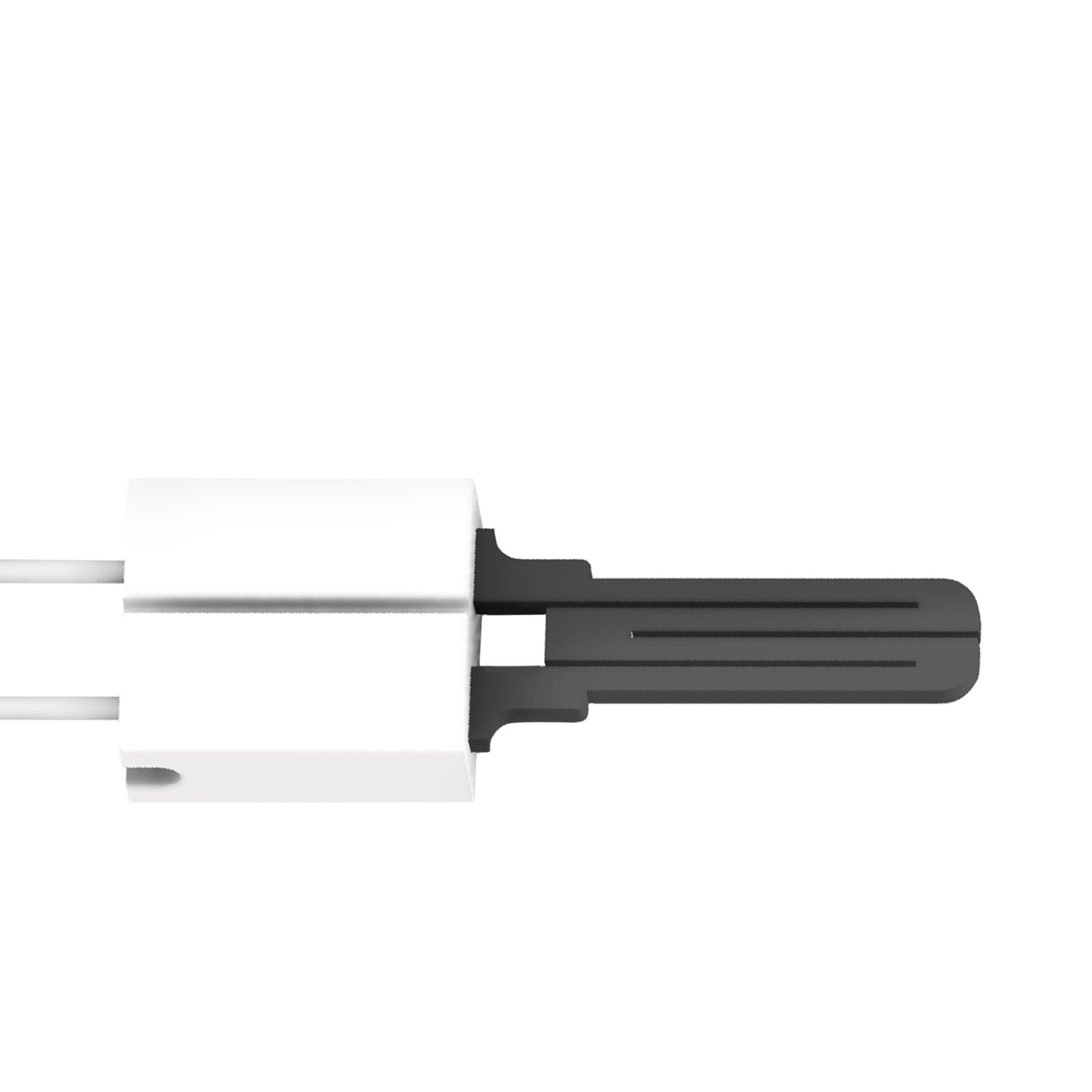

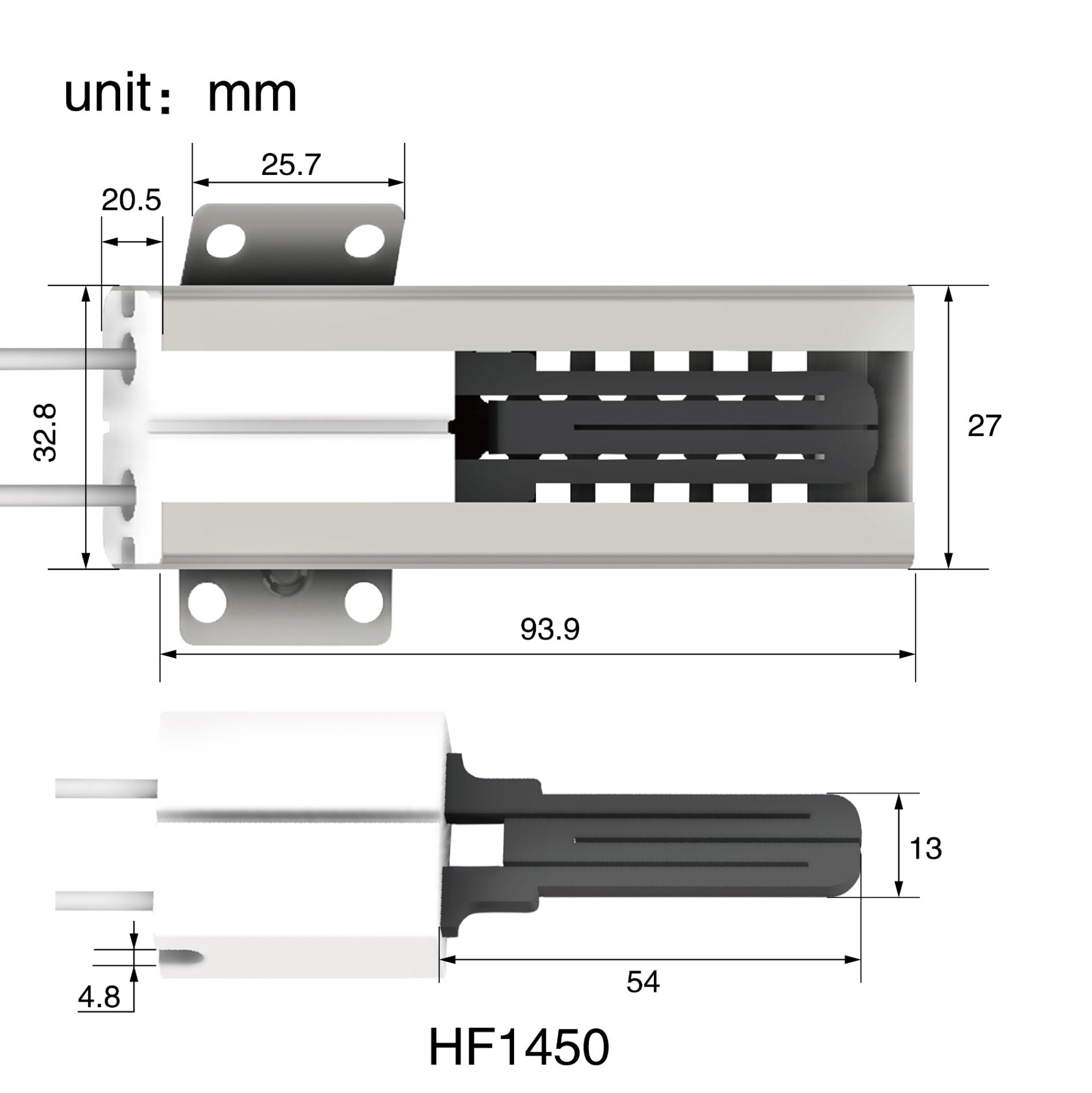

The HF1450 Furnace Hot Surface Ignitor is crafted from premium silicon nitride (Si3N4), offering exceptional thermal stability and electrical insulation. It features a customizable voltage design, with flange options including ceramic, stainless steel, and copper to suit diverse furnace configurations. The ignitor is rigorously tested to meet SGS, ISO9001, and Intertek standards, ensuring compliance with global safety and quality benchmarks.

Benefits

For industrial furnace operators, this ignitor delivers unmatched reliability and efficiency. Its rapid heating capability (1000°C in 10 seconds) slashes startup delays, while its 1100-1300°C operating range accommodates high-temperature applications. The 10-year lifespan reduces long-term costs, and the chemical-resistant design minimizes maintenance needs. By choosing this ignitor, users gain a cost-effective, durable solution that enhances furnace performance and uptime.

Use Cases

Ideal for industrial furnaces in sectors like metallurgy, ceramics, and glass manufacturing, where precise and rapid ignition is critical. It is also suitable for furnace hot surface ignitor replacement projects, offering a drop-in solution for aging systems. The ignitor’s resistance to oxidation and chemicals makes it perfect for environments with corrosive gases or high moisture levels, ensuring consistent performance in demanding conditions.

| Name | Silicon Nitride Igniter Hot Surface Ignitor | |

| Model | HF1450 | |

| Material | Silicon Nitride (Si3N4) | |

| Voltage | Customized | |

| Power | ||

| Flange | Ceramic/Stainless Steel/Copper/Customized | |

| Temp Range | 1100~1300 °C/2012~2372℉ | |

| Ignition Time | up to 1000°c in 10 seconds | |

| Samples fee | Please contact us for confirmation. | |

| Packing | Carton | |

| Lead time | 5 working days for samples; 12 working days for mass production | |

| QC | Strict quality control under SGS, ISO9001 and Intertek. | |

| Certification | BSCI, ISO9000/1400,BV TUV SGS FSC etc. | |

| Applications Customized |

||

| ·Rapid heating: Heating faster. up to 1000°c in 10 seconds ·Range of temperature:1100~1300 °C/2012~2372℉ ·Small size / High watt density: High-watt density discharge allow high thermal efficiency. ·Long working life:10 years possible,90,000 hours ·High insulation ·Direct water and kerosene heating ·Vacuum environment ·Oxidation and chemical resistance |

||

Why Choose This Furnace Hot Surface Ignitor?

This ignitor stands out with its ultra-fast heating (1000°C in 10 seconds) and long lifespan (up to 10 years), reducing downtime and maintenance costs. It is customizable for various furnace designs and tested to meet global safety standards.

How Does It Support Furnace Hot Surface Ignitor Replacement?

As a direct replacement for aging ignitors, it offers improved performance and durability. Its compatibility with multiple flange materials ensures seamless integration into existing systems.

What Makes It Resistant to Harsh Conditions?

The silicon nitride construction provides exceptional chemical and oxidation resistance, allowing it to withstand corrosive environments and high temperatures without degradation.