Description

Our Si3N4 Heater for SOFC Hydrogen Energy provides a reliable, high-efficiency heating solution for demanding industrial applications, ensuring optimal performance and durability.

Hydrogen Energy Users – Achieve Peak Efficiency with Si3N4 Heater

Ultra-Rapid Heating

Achieves up to 1000°C in just 10 seconds, significantly reducing start-up times.

High Temperature Resistance

Operates effectively in temperatures ranging from 1100°C to 1300°C, suitable for extreme environments.

Long Lifespan

Potential lifespan of up to 10 years or 90,000 hours, minimizing replacement costs.

Customizable Options

Flexible voltage, power, and flange customization to meet specific application needs.

Features

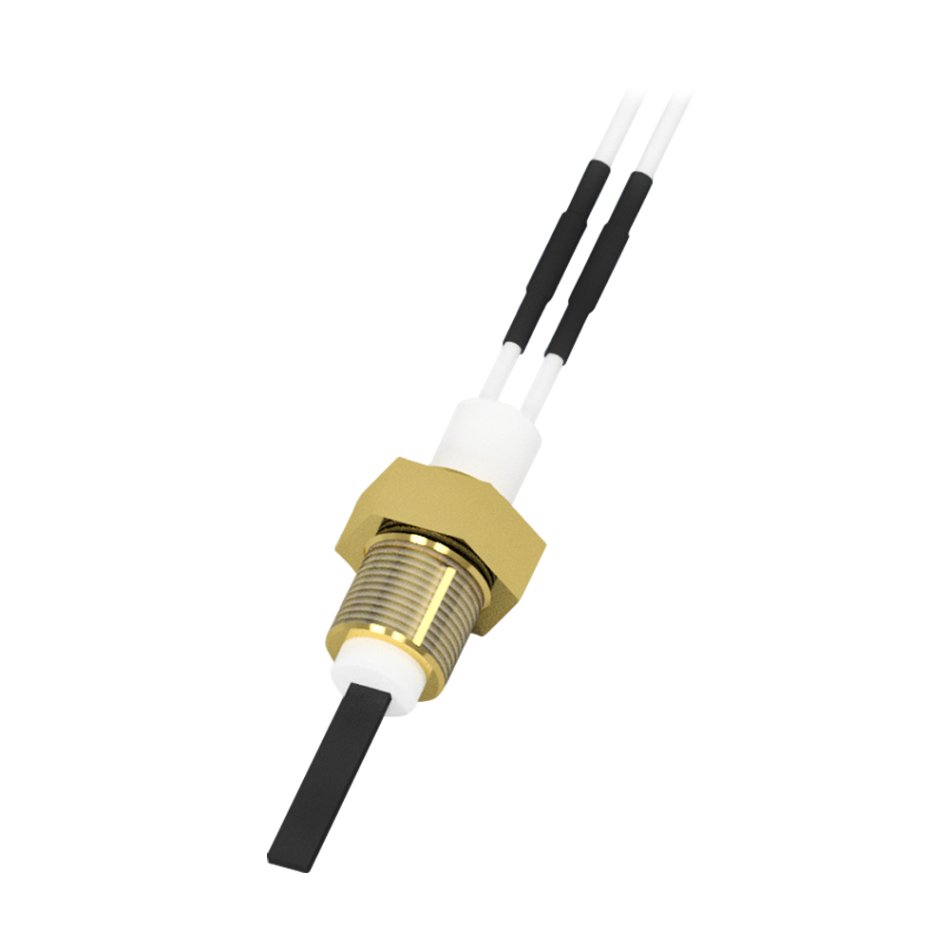

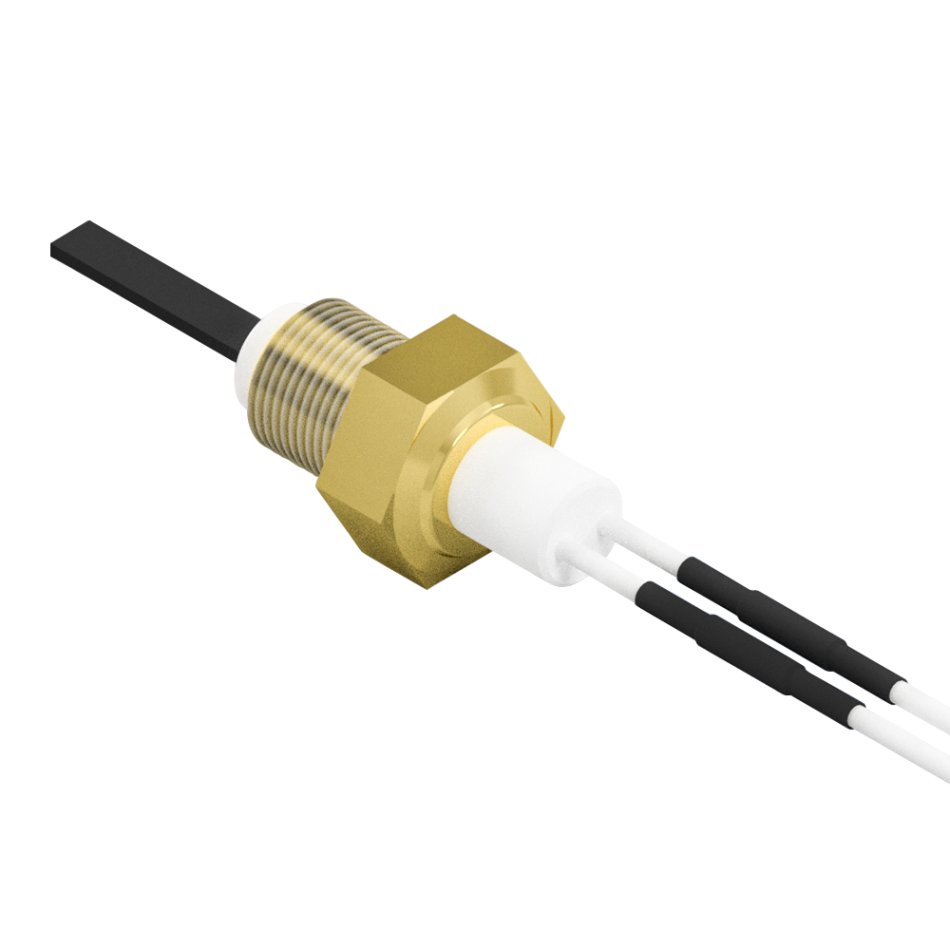

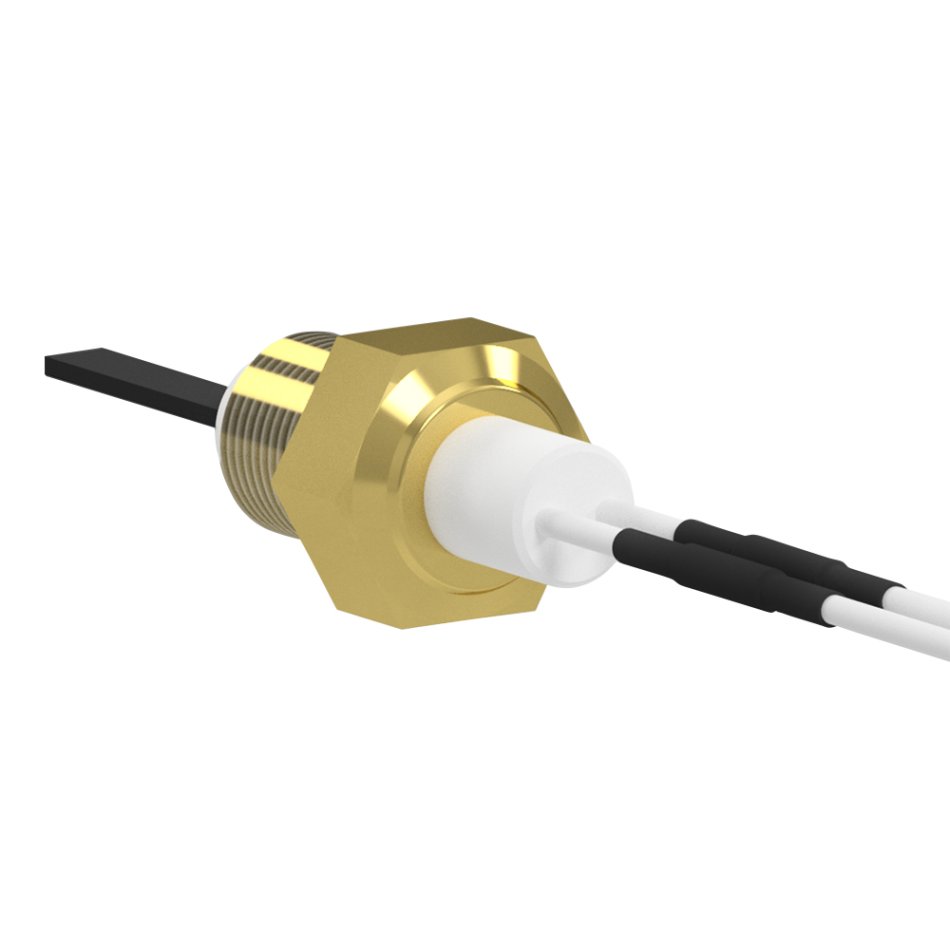

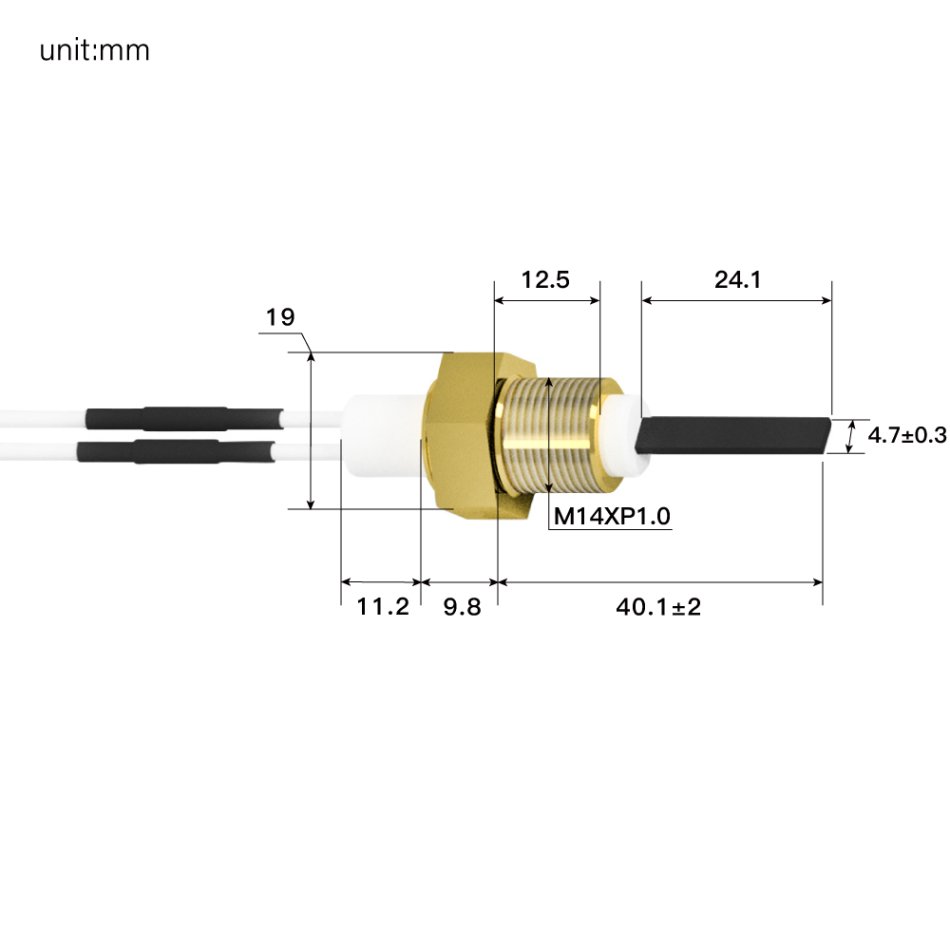

The HFHS-0701 Si3N4 Heater for SOFC Hydrogen Energy is crafted from high-quality Silicon Nitride (Si3N4), known for its exceptional thermal stability and chemical resistance. It operates within a voltage range of 90V-110V and offers power customization from 30W to 60W. The heater features a range of flange options, including ceramic and stainless steel, to suit various installation requirements.

Benefits

This heater delivers unparalleled heating efficiency, reducing energy consumption and operational costs. Its ability to rapidly reach high temperatures ensures quick start-up times, enhancing productivity. The durable construction and long lifespan minimize maintenance and replacement expenses, providing a cost-effective solution for long-term use.

Use Cases

The HFHS-0701 Si3N4 Heater is ideal for a wide range of applications, including gas furnaces, burners, kilns, and hydrogen water heaters. It is also suitable for SOFC and PEFC fuel cell systems, gas reforming to hydrogen, and post-gas combustion processes. Additionally, it finds use in laboratory equipment, biomass boiler secondary combustion, and flame detection in hydrogen combustion burners.

| Name | HFHS 0701 Si3N4 Heater For SOFC Hydrogen Energy | |

| Model | HFHS 0701 Up to 1200-1350℃ | |

| Material | Silicon Nitride (Si3N4) | |

| Voltage | 90V-110V | |

| Power | 30W-60W Customized | |

| Flange | Ceramic/Stainless Steel/Customized | |

| Temp Range | 1100~1300 °C/2012~2372℉ | |

| Ignition Time | up to 1000°c in 10 seconds | |

| Samples fee | Please contact us for confirmation. | |

| Packing | Carton | |

| Lead time | 5 working days for samples; 12 working days for mass production | |

| QC | Strict quality control under SGS, ISO9001 and Intertek. | |

| Certification | BSCI, ISO9000/1400,BV TUV SGS FSC etc. | |

| Applications

Gas furnace,burner,kiln |

||

| ·Rapid heating: Heating faster. up to 1000°c in 10 seconds ·Range of temperature:1100~1300 °C/2012~2372℉ ·Small size / High watt density: High-watt density discharge allow high thermal efficiency. ·Long working life:10 years possible,90,000 hours ·High insulation ·Direct water and kerosene heating ·Vacuum environment ·Oxidation and chemical resistance |

||

Why Choose Our Si3N4 Heater?

Our Si3N4 Heater stands out for its rapid heating capabilities, high temperature resistance, and long lifespan. It is designed to meet the demanding requirements of hydrogen energy systems, providing a reliable and efficient heating solution.

Key Features

The heater features customizable voltage and power options, a range of flange materials, and strict quality control under SGS, ISO9001, and Intertek certifications. It is suitable for various high-temperature applications in the hydrogen energy sector.

Applications

From gas furnaces to fuel cell systems, our Si3N4 Heater is versatile and can be integrated into multiple industrial processes. Its ability to withstand extreme temperatures makes it an ideal choice for hydrogen production and combustion applications.